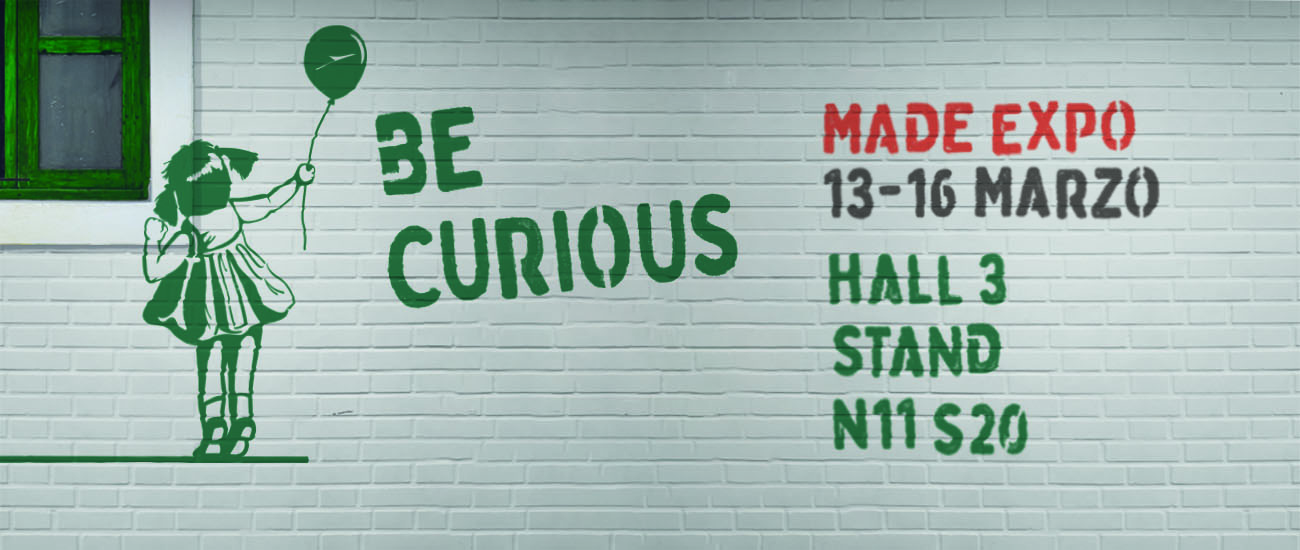

MADE expo 2019

Fom Industrie, a leader in the production of machine tools for cutting and machining

aluminium profiles, was present at the MADE EXPO with an exhibition space of 1000 sq.m. The company presence at MADE EXPO was highly anticipated by the ‘Be Curious’ marketing campaing that went viral on the company social networks.

With an annual turnover of approximately 150 million Euro and 550 employees throughout the world, the Fom Group comprises 9 manufacturing companies, 10 sales offices in the world and 55 official distributors. A network of companies structured for 360 degree management of all the phases of the production chain, capable of supplementing its offer of machinery with additional and complementary services such as workshop logistics and software developed directly by its own software house.

PRODUCTS @MADE EXPO 2019

Designed and manufactured entirely in Italy, the LMX650 line is capable of producing parts machined and cut to size using a multispindle machining centre and a sawing machine with movement along 4 controlled axes. The line also guarantees maximum flexibility for numerous aluminium profile machining and cutting applications. Depending on the configuration, the LMX650 can manage up to 50 NC controlled motorised axes. Extreme care in the design, which can be seen from the structure of the soundproof cabin at the centre of the system, and optimisation of performance are the characteristics that immediately stand out in Fom Industrie’s top of the range product. Labelling with bar in movement, vice tables upstream and downstream of the multispindle unit, blowing system integrated in the work

table guarantee machining speed and precision, but these are only a few of the features in a system that boasts six patent applications.

The occasion was used to introduce the new FMC 470 4 interpolating axes automatic nachining centre. The ergonomic lines of the new Fom protective casing, already fitted to more recent Blitz double head sawing machines, ensure excellent visibility during machining, while the illuminated logo signals the machine’s status at a glance. The machining centre distinguishes itself in the technological innovation of its patented components, such as the base and the exclusive X-FLOW dynamic tool lubrication system.

In addition to the standard demo regarding the innovation of the product,

it has also been possible for the numerous visitors to request a demo of the BLITZ doublehead sawing machines, the ADIR C 3-axis cnc and the AXEL 5 5-axis.

INDUSTRY 4.0 SOLUTIONS

LOLA:

The innovation of new machines cannot be disassociated from the integration of production processes and smart manufacturing. For this reason, Fom Industrie is offering LOLA (Log On Live Automation), a cloud-based service for monitoring and optimising the production process. LOLA, whether used on a PC or mobile device, allows the following to be checked at a glance: Machine status Process statistics

Status of electro-spindles and tools Alarms and error conditions FOM360:

The Fom Industrie Virtual Reality has been enhanced, making it possible to interact with LMX650 and FMC470 presented at MADE EXPO 2019

– The Fom Industrie service makes use of augmented reality to improve its remote assistance service. Clients could experience demo of the application and understand first hand the benefits of this technology.

– CARL (Custom Augmented Reality Layout): an exclusive app developed for Fom Industrie, allows complete and customised workshops to be created and projected in Augmented Reality (AR) mode. It is also possible to use AR to locate FOM machine tools directly in its workshop