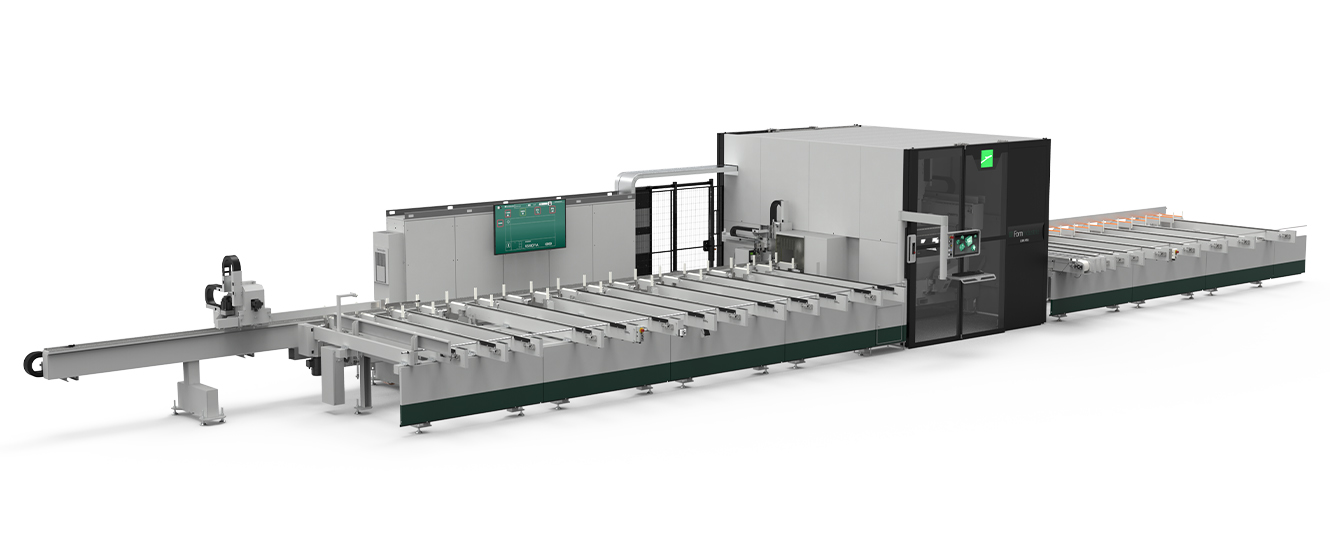

LMX650

The result of years of work and experience at Fom Industrie’s R&D department in Cattolica, LMX650 is a system capable of producing elements that are machined and cut to measure using a multispindle work centre and a sawing machine driven by 4 controlled axes.

Its flexibility makes it the ideal partner not only for customers in the door and window manufacturing industry, but also those in the continuous façade, car and furniture sectors. It can be used to process large size profiles of various shapes.

LMX650 has been created to meet the needs of an increasingly demanding market that expects a high-end product to include digital integration with the factory and management systems typical of Industry 4.0, extensive working areas, high productivity for standard mass production but also for batch-one production.

The system can manage up to 50 NC-controlled driven axes and can perform automatic format changes.

The downfeed cutting unit with continuously rotating 650mm blade and the facing mill unit make up Module X. In front of Module X is the multispindle machining unit capable of housing up to 18 electrospindles with rapid tool change (HSK) to machine the four faces of the profile. Tilting electrospindles for oblique machining operations are also available with pneumatic or controlled drive rotation.

The large soundproof cabin, housing Module X and the multispindle machining unit, guarantees great visibility for the machining operations, and the luminous Fom Industrie logo on top takes on different colours to indicate the machine status.

Extreme care in the design combines with technological research that is able to optimise the performance of the Fom Industrie system. LMX650 is covered by six patents, filed as the result of careful design, rigour, commitment and spirit of innovation that has always been a feature of Fom Industrie.

This is evident if we perform careful analysis of the interesting construction choices used, such as the vice system, designed to protect the surface of the bar being machined from scratches, by means of an integrated, patented pneumatic device that keeps the support surface of the vices themselves clean. The vices feature a series of rolling elements, which are also patented, that support the complex shaped bars in a rigid working position.

A series of sensors guarantees correct pick-up of the bar and detection of the bar length even in the presence of operator errors.

The bar loading drive device is associated with the automatic piece labelling unit (patented). The labels are applied in masked time with the bar moving, thanks to 3 driven axes that allow the bar to be followed during the machining operations. The application head is tilting and is able to apply the labels on 2 faces of the profile bar. Several sensors guarantee that each label has been properly affixed to the bar.

In this way the machined elements are stored with all the information necessary for integration with the management systems.

The plant is available with two 2 new optional devices desgined to simply the operator work and smooth the production process :

X PUSH automatic gripper change to switch from single profile cutting to cutting of profile packs.

– PATENTED –

X PULL extraction gripper with integrated suction. The gripper encourages rational filling of the unloading magazine, increasing working autonomy. The integrated suction means that cut pieces are already thoroughly cleaned and free from chips. – PATENT PENDING –

The intuitive FST CUT 2.0 interface can be used on board the machine via the adjustable control console connected to the cabin.

The LOLA (Log On Live Automation) system contribution of Fom Industrie to the IoT a cloud based service to monitor the productivity of ‘Industry 4.0 ready’ Fom Industrie machines, which is integral with the LMX650. LOLA is a user-friendly tool which provides transparent and instantly available information.

Taking advantage of sensors that are already present in the system, LOLA receives statistics on the machine status and the progress of jobs. Real time monitoring, which can be viewed with ease on the mobile platform, allows the end user to analyse productivity and the tool life cycle, making it possible to plan scheduled maintenance operations.

Serdar Kerim Demir

Hello I want to get pricing and technical Information of lmx 650 working speed service time servicing costs