Fom Industrie technological innovation: discover the news for Industry 4.0

Fom Industrie has been manufacturing and designing integrated solutions for the cutting and processing of extruded aluminium for fifty years

Fom Industrie srl, based in Cattolica ( RN), was founded in 1972 with a mission immediately clear: to create machine tools with an attractive design that meet the needs of the end customer ensuring precision execution and reliability. Innovation has always been a strategic priority for Fom Industrie that constantly invests in its Research and Development department committing resources and technical knowledge to ensure a recognized added value to the customer.

Fom Industrie is able to offer one of the most comprehensive range of high-tech machine tools on the market. The range ranges from automatic cutting and machining lines, 3-4-5 axis machining centers, lines for coupling thermal cut profiles, single and double head cross-cut saws and traditional machines.

With a turnover of over EUR 130mil further growing in 2021, and more than 500 people employed worldwide, the Fom Group comprises 10 manufacturing companies, 10 sales subsidiaries worldwide and has 55 official distributors. A network of companies structured to manage 360 degrees all stages of the production chain, able to integrate the proposal of machinery with additional and complementary services such as workshop logistics and computer programs developed internally by its own software house.

Fom Industrie chose the MADE expo showcase to present the evolution of its top of the range, the LMX2 cutting and working plant.

Alessandro Pettinari, CEO of Fom Industrie, stresses: “In compliance with current regulations and safety protocols Fom Industrie has never stopped, during the pandemic we manufactured machinery and provided the usual services to customers as well as having continued to invest in research and development projects, maintaining the commitments made in compliance with the growth and development programs launched in 2015, one of the tangible results is the launch of the new LMX2, which takes place according to the established timing’

The LMX2 is the only standardized line on the market to perform pyramidal cuts and machining on the five faces of the profile with the same machining group.

Robust, high-performance LMX2 is the high-automation plant for accurate machining of large profiles and various shapes.

Wide fields of work, high productivity and flexibility to meet different production needs are just some of the features that make it a plant designed with in mind the technological standards of digital factories and management systems of the industry 4.0. LMX2 is able to work continuously on multiple shifts, with minimal operator interaction, in fact the line can perform automatic changeovers thanks to its 50 motorized axes.

With a chain warehouse with 32 tool positions and an independent warehouse for the 500 blade, the LMX2 meets the growing automation needs of the industrial market.

In accordance with the principles of the digital factory, LMX2 as all cutting and working lines and numerical control centers of the latest generation is prepared for the use of LOLA.

LOLA (Log On Live Automation) is the web platform IIOT (Industrial Internet of Things) developed by Fom Industrie in Industry 4.0 logic for its customers to monitor efficiency, productivity, diagnostic information, periodic maintenance, ordinary and predictive of their own machine tools and plants of FOM machine tools connected to LOLA.

Through sensors already present on the machines, LOLA receives real time data on the state of the systems and on the production. The data are then consolidated so that they can be used for appropriate analysis. LOLA is a tool designed and realized following the modern trends of optimization and integration of production processes, whose ultimate aim is to increase productivity and implement predictive maintenance.

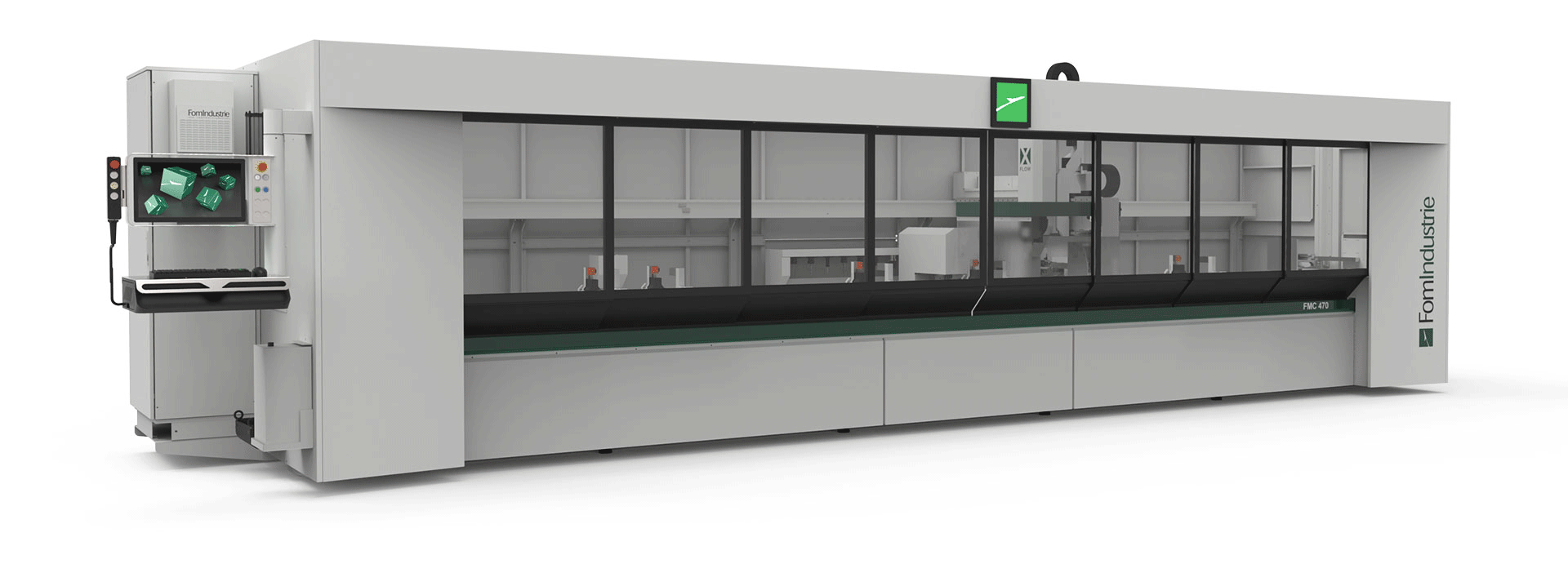

On the occasion of MADE expo will also be presented the three-axis machining center with pneumatic rotation FMC 120. Designed to perform drilling and milling operations on aluminum or steel profiles, the newborn of the FMC range confirms the sober and rigorous style of the previous series in a center dedicated mainly to the market of window frames.

Over the years Fom Industrie has been able to combine the technological level of its proposal with a research and a care in design that characterizes its plants and machine tools. Some of the features of the FMC series, particularly appreciated by customers, such as the large doors that allow visibility and ease of cleaning, are not overlooked by the most attentive observers, The bright logo Fom positioned high and clearly visible that assumes different colors depending on the states in which the machine is located and of course the ergonomic shape of the stand. In addition, the control console is always attached in a strategic position to the machine side to facilitate the operator during the use of the machine

As we said, aesthetic solutions go hand in hand with a proven technological contribution that makes the difference. The FMC series of machining centres is distinguished by its patented details such as the exclusive X-FLOW system for dynamic tool lubrication and X-PAL ( Positioning Assistant LED) the multifunctional LED bar placed on the front base that assists the operator in the correct positioning of the bars in the machine and indicates the progress of processing. All the solutions have been engineered after a careful comparison with customers and sales force present on the world market. The goal is always to offer a competitive advantage to the end customer and confirm themselves as Made in Italy ambassadors in the world.

Find out more about this Italian excellence by visiting the Fom Group booth ( HALL 3- N11S20) at the Madeexpo that will be held in Milan from 22 to 25 November, where the companies of the group will be present: FST ( Fom Software Technology) , Comall International specializes in the production of plants for thermal break profiles and logistics for workshops and Profteq manufacturer of machine tools for PVC window frames.