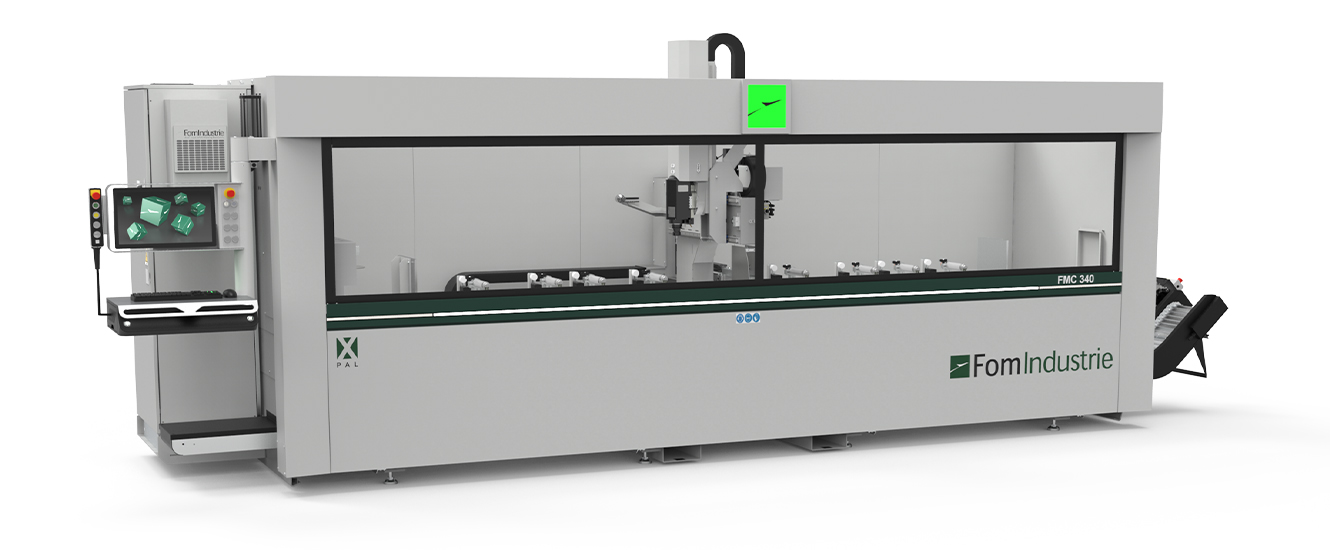

FMC 340

FMC 340 is a fully automated processing center with 4 interpolating axes for the machining of aluminium profiles with a cross section of 180×270 mm and steel tubes up to 3 mm thick.

A 7kw, liquid-cooled electrospindle with a maximum rotation speed pf 20000 rpm allows the production of custom machined and milled elements.

The ergonomic lines of the new Fom protective casing, ensure excellent visibility during machining, while the illuminated logo signals the machine’s status at a glance. The base shape is optimized to collect chips and facilitate the cleaning.

The machining centre distinguishes itself in the technological innovation of its patented components, such as the exclusive X-FLOW dynamic tool lubrication system and X-PAL (Positioning Assistant LED) the multi-function led bar situated on the basement that assist the operator in the correct positioning of the aluminium profiles and indicates the machining progress. It is also possible to add 1 rught side stops to machine simultaneous 2 bars (up to 4 bars if matched with X-PAL).

On demand a bar length machining devise is also available to detect the length of the profiles and position the machining operations accurately.

Emin

Hello my name is Emin i would like to order this equimpment please send me commercial offer term EXW

바이브 바둑이

Hello There. I found your blog using msn. This is a really

well written article. I will make sure to bookmark it and return to read

more of your useful info. Thanks for the post. I’ll certainly return.

my website :: 바이브 바둑이

Jacquelyn Garibay

At this time it looks like BlogEngine is the preferred blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

Look at my blog :: http://Soho.Nple.com/info/7788074